Briquette manufacturing control is a crucial aspect of the production process, as it ensures that the final product meets the required quality standards. This involves implementing various measures to monitor and regulate the production process, from raw material selection to the final testing of the briquettes. By controlling every step of the manufacturing process, companies can ensure that their briquettes are of consistent quality and meet the expectations of their customers.

Effective control in briquette manufacturing involves the implementation of quality control measures, monitoring and testing processes, standard operating procedures, and continuous improvement initiatives. These measures are essential for ensuring that the briquettes produced are of high quality, environmentally friendly, and meet the required specifications. By focusing on manufacturing control, companies can enhance their reputation, reduce waste, and increase customer satisfaction.

Quality Control Measures in Briquette Manufacturing

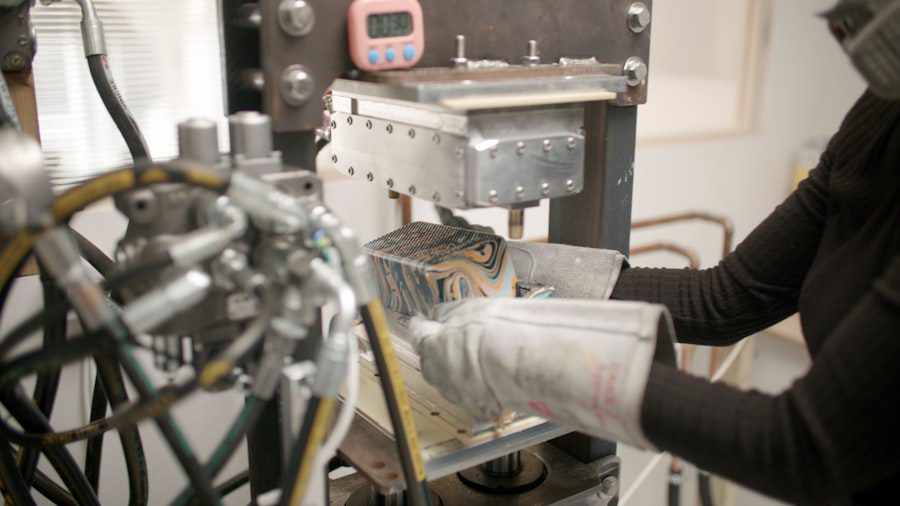

Quality control measures are essential in briquette manufacturing to ensure that the final product meets the required standards. This involves implementing various checks and balances throughout the production process to monitor and regulate the quality of the briquettes. Some of the key quality control measures include regular inspections of equipment, monitoring of raw materials, and testing of the final product.

In addition to this, companies also need to establish clear quality control standards and procedures to ensure consistency in the production process. This may involve setting specific parameters for moisture content, density, and calorific value of the briquettes. By adhering to these standards, companies can ensure that their briquettes are of consistent quality and meet the expectations of their customers. Furthermore, implementing quality control measures can also help in identifying any issues or defects in the production process and taking corrective actions to address them.

Importance of Raw Material Selection in Briquette Manufacturing

The selection of raw materials is a critical factor in briquette manufacturing, as it directly impacts the quality and performance of the final product. Companies need to carefully select and source raw materials that are suitable for briquette production and meet the required specifications. This may involve conducting thorough testing and analysis of different raw materials to determine their suitability for use in briquette manufacturing.

Furthermore, companies also need to consider the environmental impact of their raw material selection and ensure that they are sourcing sustainable and renewable materials. By using environmentally friendly raw materials, companies can produce briquettes that are not only high in quality but also have a lower carbon footprint. Additionally, selecting the right raw materials can also help in optimizing the production process and reducing waste, ultimately leading to cost savings for the company.

Monitoring and Testing Processes for Briquette Quality Assurance

| Process | Metric | Measurement |

|---|---|---|

| Moisture Content Testing | Moisture Percentage | 10-12% |

| Density Testing | Density | 0.8-1.2 g/cm3 |

| Calorific Value Testing | Calorific Value | 16-18 MJ/kg |

| Compression Strength Testing | Strength | 200-300 psi |

Monitoring and testing processes are essential for ensuring the quality assurance of briquettes throughout the production process. This involves implementing various checks and balances to monitor the quality of raw materials, as well as testing the final product to ensure that it meets the required specifications. Companies may use a combination of manual inspections and automated testing equipment to monitor and test the quality of their briquettes.

In addition to this, companies also need to establish clear protocols for monitoring and testing processes to ensure consistency and accuracy. This may involve setting specific parameters for moisture content, density, and calorific value of the briquettes, as well as conducting regular inspections of equipment to ensure that it is functioning properly. By implementing robust monitoring and testing processes, companies can identify any issues or defects in the production process early on and take corrective actions to address them.

Implementing Standard Operating Procedures for Briquette Production

Standard operating procedures (SOPs) are essential for ensuring consistency and efficiency in briquette production. These procedures outline the steps and protocols that need to be followed at each stage of the production process, from raw material selection to final testing. By implementing SOPs, companies can ensure that their production process is standardized and that all personnel are following the same protocols.

Furthermore, SOPs also help in identifying any potential risks or hazards in the production process and establishing clear guidelines for addressing them. This can help in improving safety standards and reducing the likelihood of accidents or incidents occurring during production. Additionally, SOPs can also help in training new personnel and ensuring that they are familiar with the required protocols for producing high-quality briquettes.

Training and Education for Briquette Manufacturing Personnel

Training and education are essential for ensuring that personnel involved in briquette manufacturing are equipped with the necessary skills and knowledge to produce high-quality products. This may involve providing training on equipment operation, raw material handling, quality control measures, and safety protocols. By investing in training and education for personnel, companies can ensure that their workforce is competent and capable of producing briquettes that meet the required standards.

Furthermore, ongoing education and training can also help in fostering a culture of continuous improvement within the company. By providing opportunities for personnel to enhance their skills and knowledge, companies can encourage innovation and creativity in the production process. This can lead to the development of new techniques and processes for producing high-quality briquettes more efficiently.

Continuous Improvement and Innovation in Briquette Manufacturing Control

Continuous improvement and innovation are essential for staying competitive in the briquette manufacturing industry. Companies need to constantly evaluate their production processes and look for opportunities to enhance efficiency, reduce waste, and improve product quality. This may involve investing in new technologies, adopting best practices, and seeking feedback from customers and industry experts.

Furthermore, companies also need to encourage a culture of innovation within their organization by providing opportunities for personnel to contribute ideas and suggestions for improving the production process. By fostering a culture of continuous improvement and innovation, companies can stay ahead of the competition and continue to meet the evolving needs of their customers. Additionally, embracing innovation can also lead to the development of new products and solutions that can further enhance the company’s reputation and market position.

In conclusion, briquette manufacturing control is essential for ensuring that companies produce high-quality products that meet the required standards. By implementing quality control measures, monitoring and testing processes, standard operating procedures, training and education initiatives, and fostering a culture of continuous improvement and innovation, companies can enhance their reputation, reduce waste, and increase customer satisfaction. It is crucial for companies to prioritize manufacturing control in order to stay competitive in the industry and meet the evolving needs of their customers.

When it comes to briquette manufacturing quality control, it’s essential to consider eco-friendly alternatives for sustainable living. Almassiyah’s article on “Eco-Friendly Briquette Alternatives for Sustainable Living” provides valuable insights into the importance of sustainable practices in the production of briquettes. This article discusses the various eco-friendly materials and processes that can be utilized to create high-quality briquettes while minimizing environmental impact. For more information on this topic, you can check out the article here.