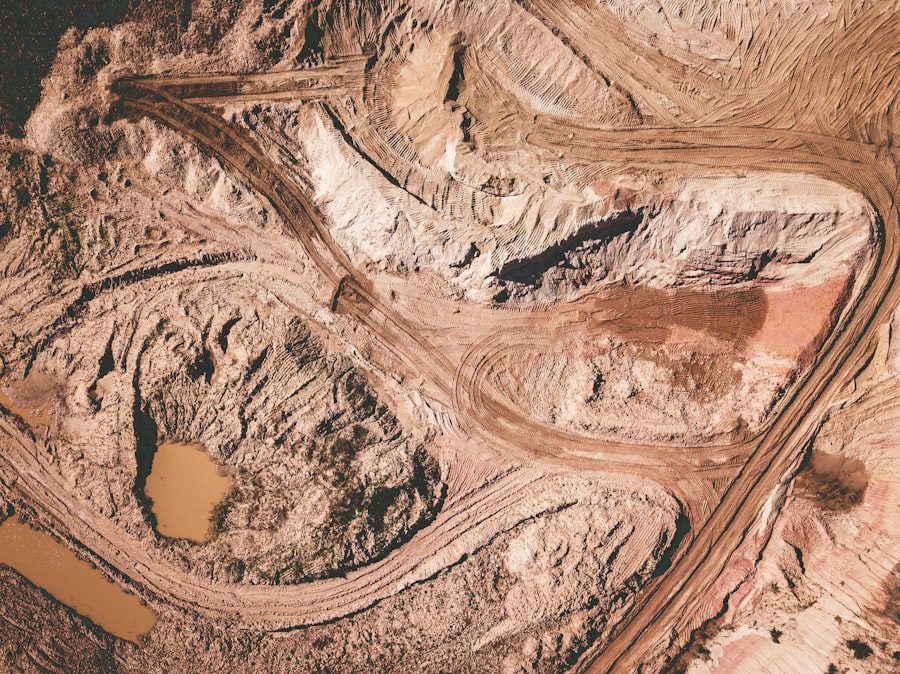

The briquette and coal supply chain is a complex network of activities and processes involved in the production, transportation, and distribution of briquettes and coal. It starts with the extraction of coal from mines or the collection of biomass materials for briquette production. Once the raw materials are obtained, they undergo processing and conversion into briquettes or coal. This involves various stages such as crushing, drying, and compacting the materials into the desired shape and size. After production, the briquettes or coal are then transported to distribution centers or directly to end-users through a series of logistics and transportation activities. Finally, the products are delivered to customers for use in various applications such as heating, cooking, and industrial processes.

The briquette and coal supply chain involves multiple stakeholders including miners, processors, manufacturers, distributors, retailers, and end-users. Each of these stakeholders plays a crucial role in ensuring the smooth flow of products from the source to the end-user. Effective management of the supply chain is essential to ensure that the right quantity and quality of briquettes and coal are available at the right time and place. This requires careful coordination and collaboration among all parties involved in the supply chain to optimize efficiency and minimize costs.

Challenges in Briquette and Coal Supply Chain Management

Despite its importance, the briquette and coal supply chain faces several challenges that can impact its efficiency and effectiveness. One of the main challenges is the variability in raw material supply, especially for biomass-based briquettes. The availability of biomass materials such as agricultural residues and forestry waste can be unpredictable due to factors such as seasonal variations, weather conditions, and competing uses. This can lead to fluctuations in production volumes and quality, making it difficult to maintain a consistent supply of briquettes to meet market demand.

Another challenge in briquette and coal supply chain management is the transportation and logistics aspect. The transportation of bulky and heavy briquettes and coal over long distances can be costly and logistically challenging. Inefficient transportation routes, inadequate infrastructure, and regulatory barriers can further complicate the logistics process, leading to delays and increased costs. Additionally, the handling and storage of briquettes and coal during transportation can also pose risks such as breakage, contamination, and theft, which can affect product quality and availability.

Strategies for Optimizing Briquette and Coal Supply Chain Management

To address the challenges in briquette and coal supply chain management, several strategies can be implemented to optimize efficiency and effectiveness. One key strategy is to diversify the raw material base for briquette production. This can involve sourcing biomass materials from multiple suppliers or regions to reduce dependency on a single source. Additionally, investing in technologies for biomass collection, storage, and processing can help improve the availability and quality of raw materials for briquette production.

Another strategy is to optimize transportation and logistics operations through route planning, mode selection, and inventory management. Utilizing advanced logistics technologies such as GPS tracking, route optimization software, and real-time monitoring can help streamline transportation operations, reduce costs, and improve delivery reliability. Furthermore, investing in infrastructure improvements such as storage facilities, handling equipment, and transportation networks can enhance the efficiency of briquette and coal distribution.

Technology and Innovation in Briquette and Coal Supply Chain Management

| Metrics | 2018 | 2019 | 2020 |

|---|---|---|---|

| Number of briquette and coal suppliers | 50 | 55 | 60 |

| Percentage of suppliers using digital inventory management | 30% | 40% | 50% |

| Investment in technology for supply chain optimization | 100,000 | 150,000 | 200,000 |

| Reduction in supply chain lead time (in days) | 10 | 15 | 20 |

Technology and innovation play a crucial role in optimizing briquette and coal supply chain management. Advanced technologies such as automation, robotics, and sensor-based systems can improve the efficiency of briquette production processes by reducing manual labor, increasing productivity, and ensuring product quality. For example, automated briquette manufacturing equipment can streamline the compaction and packaging process, leading to higher production rates and consistent product quality.

In addition to production technologies, digital solutions such as supply chain management software, inventory tracking systems, and data analytics tools can provide real-time visibility and control over the entire supply chain. These technologies enable better demand forecasting, inventory optimization, and performance monitoring, allowing for proactive decision-making and risk management. Furthermore, innovations in alternative fuel technologies such as torrefaction and carbonization can expand the range of products available in the briquette and coal supply chain, offering more sustainable and efficient energy solutions.

Sustainability and Environmental Considerations in Briquette and Coal Supply Chain Management

Sustainability and environmental considerations are increasingly important in briquette and coal supply chain management. As the demand for renewable energy sources grows, there is a greater emphasis on sustainable sourcing of raw materials for briquette production. This includes promoting responsible forestry practices, encouraging agroforestry initiatives, and supporting biomass cultivation for energy purposes. By ensuring that biomass materials are sourced sustainably, the briquette supply chain can contribute to environmental conservation and biodiversity preservation.

Furthermore, efforts to reduce emissions and minimize environmental impact throughout the supply chain are essential for sustainable operations. This can involve implementing cleaner production technologies, optimizing energy use, and reducing waste generation during briquette manufacturing processes. Additionally, promoting energy-efficient transportation methods such as rail transport or using low-emission vehicles can help minimize the carbon footprint of the briquette and coal supply chain.

Collaboration and Partnership in Briquette and Coal Supply Chain Management

Collaboration and partnership among stakeholders in the briquette and coal supply chain are critical for addressing common challenges and achieving mutual benefits. By fostering strong relationships with suppliers, manufacturers, distributors, and end-users, it is possible to create a more integrated and responsive supply chain network. This can involve sharing information, coordinating production schedules, and aligning inventory levels to ensure a steady flow of products throughout the supply chain.

Furthermore, forming strategic partnerships with technology providers, research institutions, and government agencies can facilitate innovation and knowledge exchange in the briquette and coal supply chain. Collaborative initiatives for research and development of new technologies, market expansion efforts, or sustainability programs can help drive continuous improvement in supply chain operations. By working together towards common goals, stakeholders can leverage their collective expertise and resources to overcome challenges and capitalize on opportunities in the briquette and coal supply chain.

Future Trends in Briquette and Coal Supply Chain Management

Looking ahead, several trends are expected to shape the future of briquette and coal supply chain management. One prominent trend is the increasing adoption of digitalization and smart technologies to enhance visibility, transparency, and agility in supply chain operations. This includes leveraging Internet of Things (IoT) devices for real-time monitoring of production processes, implementing blockchain technology for traceability of raw materials, and utilizing artificial intelligence for predictive analytics in demand forecasting.

Another trend is the growing focus on circular economy principles within the briquette and coal supply chain. This involves promoting resource efficiency, recycling waste materials, and extending product lifecycles through reuse or repurposing. By embracing circular economy practices, the supply chain can minimize waste generation, reduce environmental impact, and create new revenue streams from by-products or secondary materials.

In conclusion, the briquette and coal supply chain is a complex system that involves various stages from raw material extraction to product distribution. Despite facing challenges such as raw material variability, transportation complexities, sustainability concerns, there are strategies for optimization including diversifying raw material sources, leveraging technology for efficiency gains, prioritizing sustainability efforts through responsible sourcing practices, fostering collaboration among stakeholders for mutual benefit. Looking ahead, digitalization trends coupled with circular economy principles are expected to shape the future of briquette and coal supply chain management towards more efficient, sustainable operations.

Looking to optimize your coal briquette supply chain management? Check out this insightful article on Dependable Coal Briquette Supply Chain for Industry for valuable insights and strategies to ensure a reliable and efficient supply chain. Understanding the intricacies of the supply chain is crucial for businesses in the coal industry, and this article provides practical guidance for streamlining operations and maximizing efficiency.